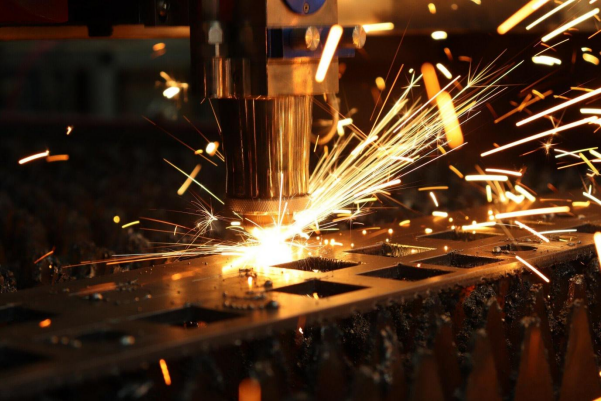

Custom Laser Cutting Solutions for Precision and Efficiency

Have you ever wondered how companies cut metal and other materials so cleanly and fast?

Custom laser cutting solutions make that possible with high precision and speed. These systems can cut shapes that are hard to do by hand. They also reduce waste and lower production time.

Many industries use laser cutting for parts, signage, and prototypes. With the right setup, businesses can improve quality and save money.

Let’s explore how custom laser cutting can boost both accuracy and efficiency.

High Cutting Accuracy

Laser metal cutting keeps the line clean and sharp, so parts fit well. When the beam moves, it follows the exact path in the file. This helps you make many parts that match each other.

The machine does not wander, so cuts stay straight and smooth. You can see the difference when you compare it to manual cutting. The edges look neat and the shape stays true.

This accuracy helps when parts must fit into other pieces. If one part is off, the whole set can fail. With precise cuts, you avoid that problem and save time.

You can cut small holes and tight curves with confidence. The beam stays stable even when the design gets complex. That makes it a good choice for detailed work.

Faster Production Times

Laser cutting moves through material quickly, so work finishes sooner. The machine does not stop and start as much as manual tools do. This keeps the flow steady and helps you meet deadlines.

You can set up a job and run it with fewer pauses. The machine follows the file without needing extra checks. This makes production feel smoother and more predictable.

When you have many parts to make, speed matters a lot. Laser cutting can handle big batches without slowing down. That helps keep the whole project on track.

Faster work also means less time waiting for parts to arrive. You can ship items sooner and keep customers happy. The whole process feels more efficient.

read more : https://wordsofrizz.com/

Cleaner Edge Finishes

Laser cutting leaves edges that look clean and neat, so you do not need heavy finishing work. The cut surface stays smooth, and you can feel the difference by touch. This makes the part look more polished right away.

Since the edge is smooth, you spend less time sanding or filing. That saves a lot of time, especially on larger projects. The work also feels less tiring when you do not need extra steps.

Cleaner edges also help when parts must join together. A smooth edge fits better with other pieces and holds tighter. This makes the final product stronger and more stable.

When you use laser cutting for signs or decorations, the finish matters a lot. The clean edge gives a sharp look that stands out. It also gives the work a more professional feel.

Reduced Material Waste

Laser cutting uses a tight beam that cuts close to the line. This means you can place shapes closer together on the material. When the layout fits well, you waste less scrap.

The machine also cuts with a steady path, so the line stays true. You do not lose extra material to uneven cuts. That helps keep costs down, especially with expensive metals.

When you reduce waste, you also reduce the need for extra material orders. That saves money and cuts down on storage space. It also makes the workflow easier to manage.

Waste reduction also helps the environment, since you use less material overall. This can be important for companies that want to work in a greener way. It feels good to run a cleaner operation.

Complex Shapes Possible

Laser cutting can handle shapes that are hard to do by hand. The beam can follow tight curves and sharp angles with ease. This gives you more freedom in design.

You can cut small details without the tool slipping or losing control. That makes it great for decorative parts and intricate patterns. The results look clean and sharp.

This ability also helps when parts need special fits or unique forms. You can design parts that match a specific space or need. The machine can bring those ideas to life.

When you create prototypes, complex shapes help test new ideas. You can adjust the design and cut a new version quickly. That makes the design process smoother and faster.

Better Design Flexibility

With laser cutting, you can change designs without changing tools. You just update the file, and the machine follows the new plan. This makes it easy to try new versions.

You can also save designs and use them again later. That saves time when you need to repeat a job. It also helps keep quality steady across runs.

If a client asks for small changes, you can respond fast. You do not need to stop and remake tools or molds. The machine adapts to new plans quickly.

Design flexibility also helps when you test new ideas. You can cut a sample and see how it fits in real life. Then you can adjust the design and cut again.

Wide Material Compatibility

Laser cutting works on many kinds of materials, so it fits many projects. You can cut metals, plastics, wood, and even some fabrics. This makes it a useful tool for many industries.

When you switch projects, you do not need a new machine. You just adjust the settings for the new material. That keeps work moving without big delays.

This also helps when you need mixed materials in one project. You can cut each part in the same shop and then assemble them. That makes production simpler and more consistent.

Wide material compatibility also helps you take on more client requests. You can offer solutions for many needs and jobs. That can bring in more work and more chances to grow.

Why Laser Cutting Matters

Custom laser cutting brings strong value to many businesses. It helps make parts with clean lines and accurate shapes. This reduces the chance of errors and saves time during production.

When work moves faster, teams can meet deadlines and handle more orders. The process also uses less material, which lowers costs and reduces waste. Companies can also change designs quickly, so they can respond to new needs.

Laser cutting works with many materials, so it fits many project types. Overall, it offers a smart way to improve quality, speed, and efficiency in modern manufacturing.

If you enjoyed this article please take the time to check out some of the other great content on our site.