Innovative Piping Solutions for Modern Construction

Key Takeaways

- Prefabricated and modular piping solutions streamline installation and save on labor costs.

- IoT-integrated smart piping systems offer real-time data and predictive maintenance, improving performance and reliability.

- Composite and other advanced materials provide strength, chemical resistance, and longevity while lowering weight and shipping expenses.

- Digital twin modeling helps simulate, troubleshoot, and optimize piping systems before and after installation.

- Eco-friendly manufacturing and water-efficient designs are essential to achieving sustainability in today’s construction projects.

Construction is changing rapidly, and so are the systems that support it. Modern builds depend on reliable, efficient, and sustainable piping methods. As urbanization accelerates and buildings become increasingly complex, contractors and engineers are seeking out the most advanced solutions available to meet demanding project timelines while also ensuring longevity and environmental responsibility. One trusted partner in sourcing reliable piping materials and innovative products is Cruco Mill & Industrial Supply, which serves the construction sector by providing quality products vital for these modern systems.

From energy-efficient skyscrapers to large-scale industrial facilities, the shift toward smarter, faster, and greener piping is evident. The right choice of piping can significantly impact installation time, ongoing maintenance costs, and a building’s environmental footprint over its lifecycle. Project leaders are no longer focused solely on function; they now also prioritize features such as real-time monitoring, sustainable manufacturing, and advanced corrosion resistance. With the support of dependable suppliers and new technologies, construction companies are better equipped to deliver projects that stand the test of time.

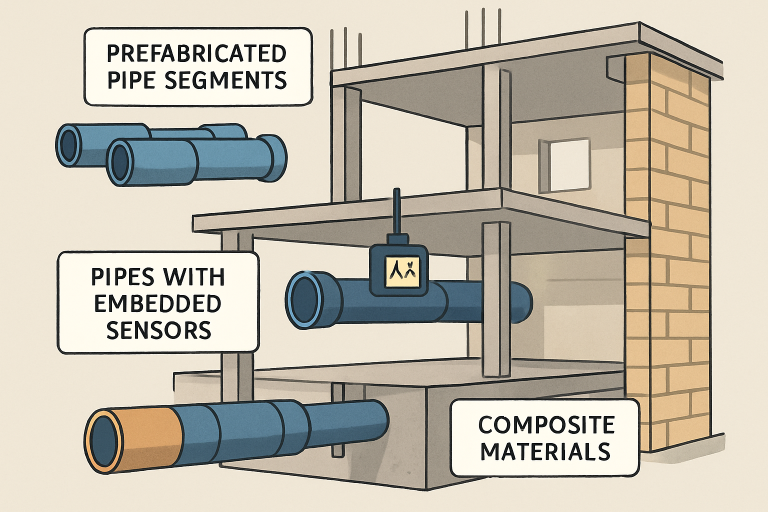

Modular and Prefabricated Piping Systems

Modular piping uses factory-assembled sections that arrive ready for installation, eliminating the traditional time-consuming on-site fabrication. This approach reduces labor requirements, speeds up project delivery, and decreases the chance of costly errors. For example, prefabricated systems played a crucial role in building a modern 10-story office complex in record time, highlighting how these approaches can transform timelines and lower disruption on crowded work sites. Modular solutions also enhance safety by reducing the number of workers exposed to on-site hazards during pipe assembly.

A key advantage is consistency, as pipes fabricated in controlled settings undergo strict quality checks before being shipped to the site. This not only reduces waste but also simplifies logistics and coordination, especially for large, multi-phase developments.

Smart Piping Technologies

The rise of the Internet of Things (IoT) has brought about a wave of innovation in piping. Smart pipes are embedded with sensors that track pressure, flow, and temperature, enabling facility managers to access performance data from any location. These insights make predictive maintenance a standard practice, as issues can be detected and resolved preemptively, preventing system failures and saving water or energy. For example, acoustic leak sensors and thermal imaging help efficiently and accurately localize water loss.

Advanced Materials in Piping

Traditional metal pipes are increasingly being replaced by composite materials made from polymers and reinforced fibers. These new materials resist corrosion and chemical attacks common in industrial and commercial environments. The lightweight nature of composite pipes makes them easier to handle and transport, lowering installation costs and reducing stress on building structures. They are also suitable for diverse applications, from potable water delivery to harsh chemical processing.

In addition, composite pipes support sustainability goals by extending replacement cycles and minimizing resource consumption. Their reliability under extreme conditions, such as high pressure or temperature, makes them a top choice in challenging environments. To learn more about material innovation in the construction sector, check out Architectural Digest.

Digital Twin Technology

Digital twin technology is empowering engineers to visualize piping systems in a virtual environment before installation begins. By creating a complete digital replica, teams can analyze flow dynamics, identify inefficiencies, and test how the system will respond under different conditions. These simulations enable proactive improvements and reduce risks during commissioning. Additionally, the digital twin acts as a living record through the building’s lifespan, tracking wear, component history, and maintenance needs.

Digital twins can also be tied directly to facility management platforms, feeding data from smart pipes into the virtual model for real-time optimization of performance and energy use.

Sustainable Manufacturing and Water-Efficient Systems

Sustainability is an overarching theme in piping innovation. Manufacturers are investing in low-impact processes, such as 3D printing and recycled materials, to reduce waste and energy consumption during production. More projects are prioritizing water-efficient features, such as piping layouts that support rainwater harvesting, greywater reuse, and leak detection to curb unnecessary loss.

Water conservation is both an ecological need and a regulatory priority. By integrating efficient piping design and sustainable manufacturing, construction projects are achieving higher environmental ratings and reducing long-term operational costs.

Conclusion

The future of construction depends on the smart adoption of advanced piping solutions. By leveraging modular systems, embracing digital twins, installing smart sensors, and supporting green manufacturing, the built environment is growing more resilient and resource-conscious. Companies that collaborate with trusted suppliers and stay at the forefront of these trends will consistently deliver value on every project.